Figure 1

APL CEO Andrew Spencer, Australia’s CVO Dr Mark Schipp and Biosecurity Strategic Review Panel Chair Gardner Murray.

ENERGY Networks Australia and Bioenergy Australia recently hosted a Renewable Gas Symposium in Sydney. This symposium explored emerging innovations and research in hydrogen and biogas.The drivers pushing businesses to consider utilising low carbon gas and the injection and policy mechanisms needed to support it being blended into existing gas networks.

It was evident that major gas corporations across Australia are committing to the development of hydrogen energy projects and there are currently 10 projects being piloted in development across the country. Hydrogen can play an important role in helping Australia’s gas networks decarbonise and store energy.

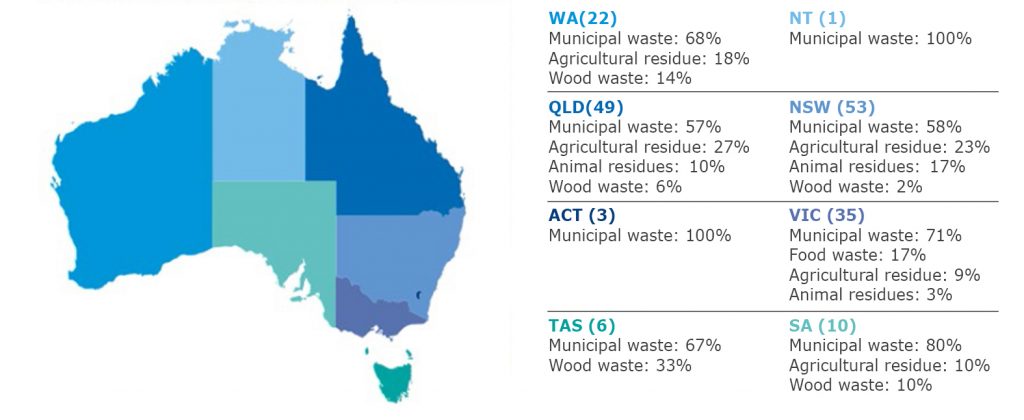

Biogas is also considered to be very important to the development of hydrogen technology as it is one of the cheapest forms of energy, particularly when waste products are used to produce it. Hydrogen is expensive to produce and transport but can be utilised in electric vehicles (think hydrogen fuel cells), with the by-product (exhaust) being water. In 15-20 years, the thought is there will be a blend of biogas and hydrogen in gas networks to reduce CO2. Energy Networks Australia has produced Figure 1 on renewable gas sources.

So, what does this mean for pork producers? Currently, about 15 percent of the industry produces biogas from covered anaerobic ponds for its own heating, cooling or electricity needs. Some producers also feed the surplus energy into the electricity grid. The information presented at the conference clearly shows biogas is an important contribution to the renewable gas sector.

The Symposium included a presentation from the Ministry of Foreign Affairs from Denmark, which discussed the steps taken to develop their biogas industry. This included a commitment to reducing methane output from agriculture where it has been mandated that 50 percent of manure by-product must be utilised in biogas production by 2020 and this includes a 20 percent investment grant to develop the technology.

Key challenges to the development of hydrogen energy include:

- Two-thirds of energy is lost in conversion;

- It is costly to produce;

- Problematic to transport;

- Producing it at scale requires a lot of power; and

- Scale-up requires investment.

In addition to the development of hydrogen energy, the Australian biogas industry has significant untapped potential.

- The investment opportunity for new bioenergy including biogas projects is estimated at $3.5-5 billion. Biogas also has the potential to avoid up to 9 million tonnes of CO2-e emissions each year.

- Value drivers include:

- Continuous and dispatchable energy source;

- Renewable energy;

- Produces energy from waste; and

- Supports local economies and regional communities.

As a renewable natural gas, biomethane can replace natural gas by being injected into the existing gas grid. Therefore, it can provide a cleaner energy to large industries, business and households as well as fuel for vehicles. Water treatment facilities, such as Sydney Water, are also beginning to use biogas to help offset costs.

It is acknowledged there are still cost, regulatory and policy constraints that hinder the ability to tap the full potential of these technologies in Australia. However, it is refreshing to see these options are being presented as a potential solution to energy generation throughout Australia.

Visit by Dr Mark Schipp, Australia’s CVO to Australian Pork Limited

APL’s Biosecurity Strategic Review Panel, chaired by Dr Gardner Murray, includes members from the Department of Agriculture, Animal Health Australia and pig veterinarians. The Panel meets quarterly to discuss and provide constructive feedback on Australia’s preparedness for exotic and endemic disease and identify RD&E needs and key risks for the Australian pork industry.

Following an invitation from the panel, Australia’s Chief Veterinary Officer Dr Mark Schipp attended the Panel meeting on May 14, 2019 and discussed the role of the CVO, the Department’s biosecurity priorities and activities, World Organisation for Animal Health matters, antimicrobial resistance and African swine fever.

Some interesting results:

Dr Kate Plush from SunPork Solutions recently completed an APL-funded study aimed at reducing litter weight variation. It is well recognised that variation in litter birth weight can affect pork production from the time of birth through to slaughter. However, there is little published information on the seasonality of variation in piglet birth weight.

It has been shown that feeding dextrose to sows can reduce variation in litter weight but this has not been tested during summer. This study aimed to test the effectiveness of dextrose administration in a ‘wean to mate’ diet to sows at alleviating within litter weight variation during summer and determine whether variation in piglet birth weight is influenced by season.

Evidence for increased piglet birth weight variation in sows bred during summer despite the reduced litter size was obtained. This finding is concerning as it suggests seasonal infertility can also result in increased within-litter variation. Interestingly, the inclusion of 5 percent dextrose in the ‘wean to mate’ sow diet increased litter size without affecting litter birth weight variation.

Feeding 5 percent dextrose in a ‘wean to mate’ diet also resulted in less piglet removals and higher growth rates overall in piglets born to sows mated in winter (lactated in summer). While this may suggest the applied treatment improved piglet vigour, this remains to be confirmed.

So, what are the costs involved?

Dextrose is easy and safe to handle and its inclusion in the diet is relatively cheap. At about $1000 per tonne and 5 percent inclusion, the cost is $55 per tonne of feed milled. With a wean to service interval of five days and feed consumption of 3.5kg per day, the application cost is less than $1 per sow.

Using the reported farrowing rate of 82 percent and 13.7 piglets born alive, the benefits far outweigh the costs if farrowing house management is adequate.

Per 100 sows bred, the number of piglets born alive improved from 931 to 1118 using dextrose during the wean to mate period irrespective of season.

Though this may all seem rather promising, farms could find it difficult to order and store if volumes required are low and/or there are limitations on silo space. To exploit the advantages identified in this study, it was recommended daily feed allowance of sows be top-dressed with about 190g of dextrose until breeding.

This is easy to achieve in systems that wean into breeding stations but will be more complex in group-weaned farms.

For further information on items discussed in this article, please contact me on 0423 056 045 or heath er.channon@australian pork.com.au

Heather Channon

Australian Pork Limited, Research and Innovation General Manager