In the July edition, I wrote about how preparing your piglets in the farrowing unit will set them up for optimal gut health for the rest of their lives and assist in reducing the nutritional stress associated with the weaning process. Feeding and management are of course, keys to achieving healthy pigs and high growth rates, however the environment in which they are raised can often be overlooked.

Of course, the environment should be clean and hygienic to reduce the infection pressure applied to the animals, but what I am referring to is the design of the pens and the space allocation for the animals. A lot of practical research has been done in Denmark by SEGES Danish Pig Research Centre to identify the key components of weaner pen design, which is important for growth and health.

In this issue, I am going to highlight the main physical recommendations of the pen design, as the temperature and feeding recommendations are for a separate article, or two. In standard Danish production systems, piglets are weaned at four weeks and moved into the weaner unit, where they stay until 30kg, generally 11 weeks old. Depending on the production system, the animals will then either be moved to a grower finisher pen or exported for grow out elsewhere, predominantly Germany. No more than 30 weaners should be penned together and, wherever possible, keep litter mates together to reduce stress and aggression.

Pens should have a length to width ratio of 2:1 and allow for an unhindered path between the eating and drinking area, resting area and dunging area – so that any animal can move around where they choose.

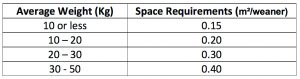

Eight hours of light per day should be provided with a luminous intensity of at least 40lux. The table shows the recommended minimum area for each piglet according to their weight.

It is recommended that each pen be one third slatted flooring and the rest solid. The gaps in the slatted floor should be no wider than 14mm and the beam width between them at least 50mm. Usually, the solid flooring is at the furthest end from the aisleway and provides comfortable resting areas for the weaners.

In many farms, a small amount of shavings or straw is placed in the solid end, with some installing a lip also to keep the straw in. If this is the case, the lip should be no higher than 15cm to allow pigs to easily step over it. Dual climate pens allow pigs to create their own local environment. This is done by putting a cover over the pigs bedding area, where the weaners’ own heat production contributes to heating the room under the cover, allowing the rest of the room to stay relatively low in temperature. The cover should be placed at a height of 70cm, with the opening to the weaners between 40-60cm, as a 10cm lip should be included at the front.

Each weaner should have a minimum space of 0.8sq m under the cover. In modern production sites, these covers are able to be raised and lowered automatically in response to temperature sensors, but a simple winch can also work well if staff are observing weaner behaviour. It is important in these systems that the creep does not become too hot, as piglets will dung in the wrong area and cause hygiene issues that are hard to stop.

Both nipple drinkers and drinking bowls can be used for weaners. Nipple drinkers ensure water is always fresh whereas bowls can attract weaners to drink – while they are able to service more animals than nipple drinkers, regular cleaning is critical to manage bowls. Further specifications for the management and installation recommendations are available, depending on production preference, but the key point for both is for a minimum flow rate of 0.5-0.8lpm and provision of cool fresh water.

Cooling systems are recommended to be installed as overhead sprayers, mounted 2m above the floor and set to shower for two to three minutes, three times an hour in summer. As ‘summer’ is classified as above 18C, I expect that, given the climate difference, there has been far more research done on this aspect in Australia, so I won’t go into further detail here. I have only highlighted the main points to consider in the design of your weaner pen.

If you would like more detail or specifications, contact me at asno@danbred.com